- Prolonged shutdowns in Vietnam because of the coronavirus pandemic are becoming a bigger headache for retailers.

- The worries led Wall Street research firm BTIG to downgrade shares of Nike last week, citing serious production issues since the sneaker maker last reported earnings.

- The picture will likely grow bleaker as the holidays near.

Prolonged coronavirus restrictions in Vietnam have become a bigger headache for retailers, particularly those that rely on the region for manufacturing footwear and apparel, as the holiday season approaches.

The worries led Wall Street research firm BTIG to downgrade Nike shares last week. BTIG cited serious production issues for the sneaker maker since it last reported earnings. Supply chain challenges are expected to be a hot topic when Nike's next fiscal quarter financial report drops after the stock market closes next Thursday.

The troubles go beyond Nike. The risk has grown for a number of other retailers, which have been hampered by supply-chain delays as they wait for production facilities in Vietnam to get back up and running, according to recent comments to analysts and investors.

Get Philly local news, weather forecasts, sports and entertainment stories to your inbox. Sign up for NBC Philadelphia newsletters.

The difficulties have even made some companies reconsider decisions to move production out of China and into Vietnam.

On Monday, authorities announced a two-week extension of restrictions in Ho Chi Minh City, Vietnam's business hub and Covid outbreak epicenter. Under the restrictions, factories have been subject to rules that require them to either keep workers on site or completely suspend operations. Experts also note that restrictions in northern Vietnam have not been as stringent as rules in the southern part of the country.

Some retailers have expressed hope the pressure will ease. Leggings maker Lululemon has said it anticipated factories in Vietnam would start a phased reopening in the middle of September.

Money Report

The high-end furniture chain RH, meantime, has targeted a restart in southern Vietnam in October. It hopes to ramp up production to full capacity by the end of the year.

The manufacturing slowdown, coupled with longer transit times and heightened transportation costs, led RH to delay the launch of its contemporary furniture collection until next spring. It also delayed mailing fall catalogs.

For now, many businesses are watching and waiting to see how the restrictions and manufacturing activity will evolve. But the picture will likely grow bleaker as the holidays approach.

The obstacles in Vietnam join a litany of other supply chain troubles, ranging from a shortage of cargo shipping containers to backlogged ports and a limited number of truck drivers. Some companies that moved manufacturing out of China and into Vietnam in the past few years — in a bid to diversify their supply chains and avoid tariffs — have gone as far as to say they are bringing production back to China.

During a presentation with investors last week, Designer Brands Chief Executive Officer Roger Rawlins said he spoke to another industry CEO who told him that because of the slowdown in Vietnam, six years of supply chain work was undone in six days.

"When you think about the amount of effort everyone was putting into getting out of China, and now one of the only places where you can get the goods is China," Rawlins said. "It really is crazy, the roller coaster everyone has been on here."

Rawlins noted that because Designer Brands sells less workout apparel and performance footwear, such as running and basketball shoes, the company has fared better than some of its peers through the lockdown measures in Vietnam. Categories including so-called athleisure have traditionally relied on the country.

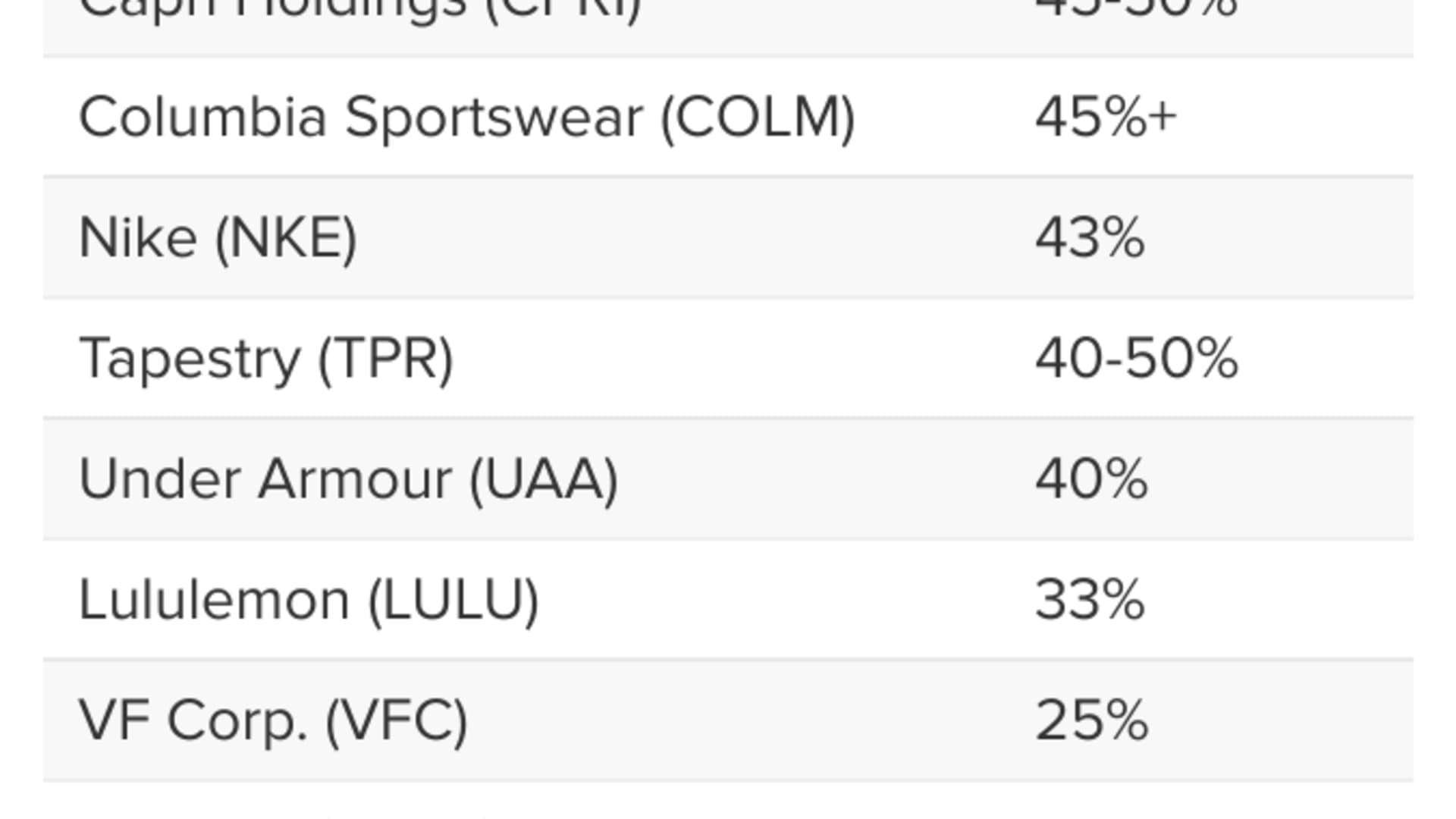

The retail companies with some of the greatest exposure to Vietnam include Ugg and Hoka parent Deckers Outdoor, Michael Kors parent Capri Holdings, Columbia Sportswear, Nike, Coach owner Tapestry, Under Armour and Lululemon, according to an analysis by BTIG.

Manufacturing troubles in Vietnam may not have much effect in the third quarter, BTIG analyst Camilo Lyon said in a report to clients. It could cause more issues in the fourth and holiday quarter and likely into the first half of next year, Lyon said.

"Many brands have proactively cut orders in anticipation of capacity constraints and backlogs once factories are back up and running post-lockdown," Lyon noted. "Many larger brands have moved or attempted to move some production to other countries."

Products tracked by BTIG that normally take about three months to produce in parts of Asia are now taking 12 weeks longer because of backlogs.

"It may take 5 to 6 months for factories to be back up and running normally post-lockdown," Lyon said. "This includes 4 to 5 weeks of delay in receiving raw materials and another 8 weeks for a factory to work through its backlog of production."

Factories in Vietnam will also likely have trouble getting workers to return after authorities lift Covid-related restrictions, BTIG said.

Urban Outfitters CEO Richard Hayne told analysts in late August that the retailer's biggest concern has been receiving inventory, specifically dresses and bottoms that have been on order from Vietnam.

"We have a situation in Vietnam ... where the country is completely closed," he explained. "We have a lot of product there, and we're trying to get it in."

A few months earlier, Covid outbreaks made India a trouble spot for the retail industry, before conditions improved there, Urban Outfitters said. Vietnam then started to pose challenges, the company said.

Donna Dellomo, CFO of the furniture company Lovesac, said the company has shifted orders out of Vietnam and back into China to try to minimize risk.

"We know that the inventory that comes in from China is impacted by tariffs, but it allows us to stay in-stock on our inventory, which is super important to us, as it is to our customers," she said on an earnings conference call earlier this month.

Nike produced some 350 million pairs of sneakers in Vietnam last year, BTIG estimated. The research firm predicts as many as 160 million pairs might not be made this year because of the shutdowns.

Nike declined to comment, as the company is in a quiet period ahead of its earnings report.

— CNBC's Michael Bloom contributed to this reporting.